Trough belt conveyor are a common type of material-handling equipment designed for inclined angles. It is typically installed at an angle of over 22° and can be installed vertically. The conveyor belt features ribs and transverse partition, which effectively prevent materials from scattering and adapt to a variety of materials.

The operational principle of a trough belt conveyor is identical to that of a standard belt conveyor. Its primary function is to optimise the use of space. The transverse partition and corrugated ribs on the conveyor belt effectively prevent material from falling, enabling the conveyor belt to complete the conveying work in narrow spaces.

Product Features

• Large tilt angle

• Small footprint

• Large conveying capacity

• Used in conjunction with ordinary conveyor belts

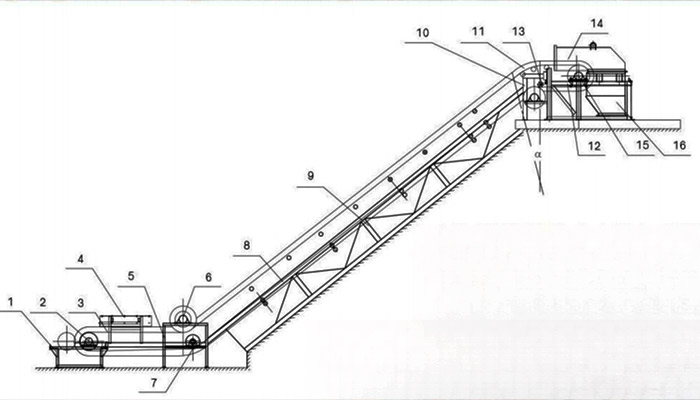

Product Structure

1. Tail Bracket (With Tensioner) 2. Tail Bracket 3. Trough Belt 4. Guide Chute 5. Concave Section Supprot 6. Pinch Roller 7.Bend Wheel 8. Middle Bracket 9. Middle Support 10. Protruding Section Support 11. Protruding Section Bend Wheel 12. Head Bracket 13. Beater 14. Head Cover 15. Driving Roller 16. Hopper

Product Technical Parameters

| B (mm) | Height of ribs (mm) | V (m3/h) | B (mm) | Height of ribs (mm) | V (m3/h) |

| 500 | 80/100 | 84/111 | 1400 | 200/240/300/400 | 920/1295/1655/2380 |

| 650 | 120/160 | 140/185 | 1600 | 200/240/300/400 | 1075/1515/1955/2805 |

| 800 | 120/160/200 | 185/317/359 | 1800 | 240/300/400/500 | 2200/2725/4105/5035 |

| 1000 | 160/200/240 | 425/480/680 | 2000 | 240/300/400/500 | 2480/3235/4645/5735 |

| 1200 | 160/200/240/300 | 535/765/1075/1360 | 2200 | 300/400/500/600 | 3610/5190/6430/7819 |

The data is calculated according to the belt speed and angle, but may differ in practice. The final data is subject to the product design drawings.

CAFU is a professional designer and supplier of bulk material handling equipment. We look forward to receiving your enquiry at any time. Our engineers will provide you with the best incline (trough) belt conveyor to suit your needs.