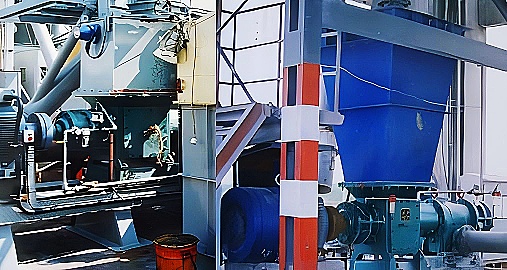

Pneumatic Conveying System for Screw Pumps in the Cement Industry

Our M-type cement industrial pneumatic conveying screw pump features advanced structural design and exquisite manufacturing process. It offers long conveying distance, high conveying capacity, and wide application range. It is the main pneumatic conveying pump for continuous bulk material conveying in cement plants, suitable for materials like cement, raw meal, coal powder, gypsum powder, and aluminum powder with a temperature below 200 ℃.

The M-type cement industrial pneumatic conveying screw pump is a state-of-the-art solution for efficient material handling in the cement industry. With its advanced design and high-quality construction, this pump offers exceptional performance and reliability.

Key Features:

- Long conveying distance

- High conveying capacity (Max. 300t/h)

- High conveying height

- Wide application range

Applications:

- Feeding of raw meal metering in the pre-calcined system at the kiln tail

- Provision of proportionally adjustable coal powder for the combustion system

- In-plant conveying of dry bulk materials from the mill (or silo)

- Ash return conveying in dust collection systems

- Loading and unloading of bulk cement

Professional Services:

- Optimization design of system supporting equipment

- Steel structure design of the pneumatic conveying system

- Supply of complete sets of equipment

- Full technical support

M-type Screw Pump Selection Table:

|

Specifications |

Pitch |

Capacity(m3/h) |

Raw meal(t/h) |

Cement(t/h) |

Pulverized coal(t/h) |

||

|

Volume weight(kg/m3) |

Specific surface area(cm2/g) |

Volume weight(kg/m3) |

|||||

|

1040 |

880 |

3400 |

3600 |

560 |

|||

|

M150 |

150X100 |

12.5 |

12.5 |

11.2 |

18.5 |

17.8 |

7.2 |

|

M200 |

110X75 |

30.5 |

29.5 |

25.2 |

43.5 |

41 |

16.7 |

|

150X100 |

40.2 |

40.5 |

34 |

59.5 |

56 |

22.5 |

|

|

190X120 |

50 |

52.5 |

43.5 |

75 |

71 |

27.5 |

|

|

M250 |

140X90 |

68.5 |

71 |

60 |

103.5 |

98 |

38.5 |

|

190X120 |

92.5 |

95 |

80 |

138 |

130 |

52.02 |

|

|

230X150 |

108.5 |

112.5 |

95 |

165 |

155 |

61.05 |

|

|

M300 |

180X115 |

142.5 |

148 |

125 |

216 |

203 |

80.06 |

|

220X140 |

170 |

176.5 |

148 |

255 |

242 |

- |

|

|

260X165 |

196.5 |

204.5 |

172 |

298 |

281 |

- |

|

|

300X190 |

230 |

239.5 |

202 |

347.5 |

330 |

- |

|

|

M350 |

240X165 |

283 |

296 |

250 |

425 |

405 |

- |

|

330X240 |

370 |

385 |

325 |

560 |

531 |

- |

|

The above data are for reference only, and the actual output may vary due to different processes.

Choose our pneumatic conveying system for efficient and reliable material handling in your cement plant. Contact us today for more information and a customized solution.