We manufacture customised wear resistant steel plate parts for mining and aggregate production as well as for the cement industry. From the outset, we use high-quality wear plates, including HARDOX wear plates from Sweden and high-quality local Chinese wear plate brands.

Our suppliers of raw materials are all authorised distributors of wear plate manufacturers, which guarantees the quality of the material. The machined parts are accompanied by original quality certificates.

We are a trusted provider of the wear resistant steel plate parts. We produce high quality, replaceable machine components that are exposed to high levels of wear. We use cost-effective wear plates from China to customise your wear parts. The raw materials combine high hardness, strength and toughness and can therefore be used in a wide range of applications such as loading, conveying and crushing.

1. Design Services:

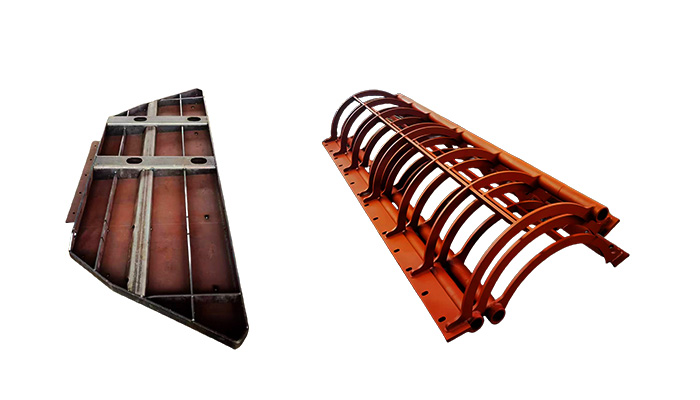

• We customise wear plate parts to your drawings. If you only have hand drawn drawings, that is not a problem at all, our mechanical engineers will work as fast as possible to complete the specification drawings for your confirmation.

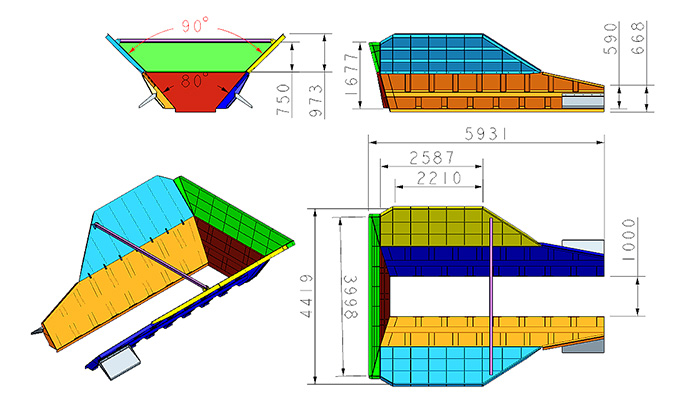

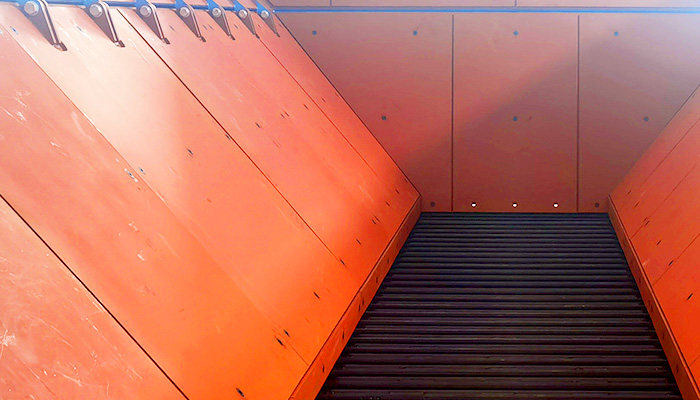

• Our heavy duty wear resistant customised hoppers, designed to customer requirements and lined with NM400, are tailor made for aggregate crushing.

2. Ensure Installation:

• The wear steel plate liners made of NM400 are precisely fitted to the feed hopper.

• Supplying the highest quality mining and quarrying wear resistant steel plate parts is our speciality. Our specialised machining equipment along with expert manufacturing engineers will be able to ensure that all wear resistant liner parts are effortlessly installed on site.

3. Type of Customisation:

• In addition to customised wear-resistant liners, we also customise wear-resistant support structures made from wear-resistant plates for our major users.

4. Materials:

• A wide range of high performance wear resistant steel plates, ultimately based on your application.

5. Applications:

• Mining and Quarrying.

Machinery and equipment in mines and quarries are challenged by abrasive wear of aggregates and strong impacts. Our wear-resistant steel plate solutions can help you meet these challenges to ensure productivity and cost-effectiveness.

• Cement Industry

The equipment used to handle and transport the aggregates needed to make cement requires wear-resistant steel plate solutions. Wear occurs during excavation, crushing, screening, mixing and conveying.

• Asphalt Plants

Asphalt mixing takes place at high temperatures. Highly abrasive aggregates can accelerate wear on equipment.

• Energy Production Plants

The wear-resistant steel plate parts are used in power generation plants. They ensure reliable production.

• Steel Industry

Conveying and storage systems for the steel industry.

We understand the wear parts needs of the cement industry, mining and aggregate crushing production processes. With our extensive experience working in these specific industries, CAFU is able to act quickly when supplying the wear-resistant steel plate parts, focusing on your uptime and supplying you with wear-resistant steel products in a timely and efficient manner.